W’wave® Windwave Optimizes Wind to produce more competitive wind energy

INTRODUCTION to our TECHNOLOGY

Until today, wind conditions (wind speed, turbulence, wind shear) have been considered technical parameters that cannot be changed voluntarily in a wind farm. Wind developers need to measure it and they have to “live” with what they have.

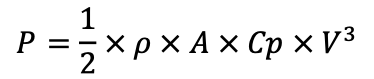

What if we were able to improve artificially such wind conditions? We might see a considerable improvement considering wind power increases with the third power of the wind speed:

P = Wind Power

r (Rho) = Air density

A= Rotor Area of the wind turbine

Cp = Wind Power coefficient of the wind turbine

V= Wind speed

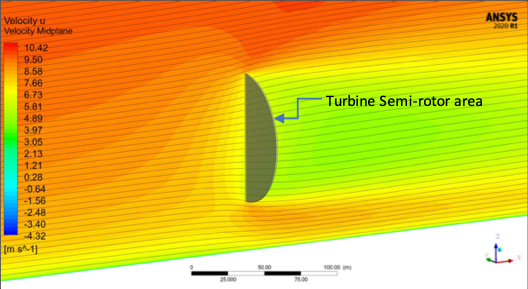

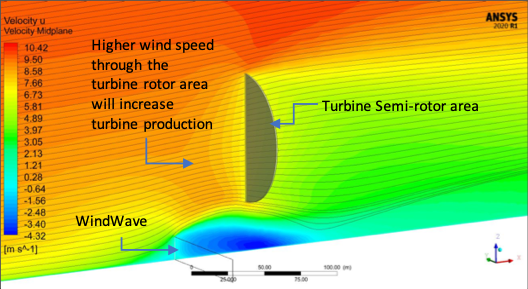

See Computational Fluid Dynamics (CFD) graphs below.

Colormaps indicate increase in wind speed through the turbine’s rotor thanks to the Concentrator effect.

<- Wind Speed profile Without WindWave

Wind turbines harvest kinetic energy from wind. Wind speed (and wind energy) typically grows with height (wind shear)

Wind Speed profile With WindWave ->

The WindWave enables a wind speed increase in the wind rotor area, shifting kinetic energy to the rotor area, where the wind turbine can harvest it.

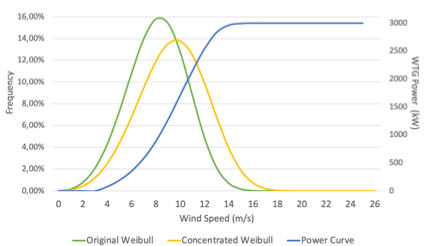

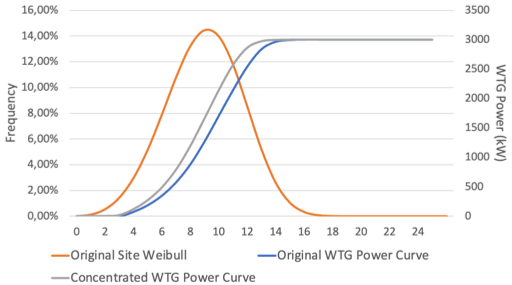

Impact on the Wind Farm’s Wind Speed Frequency Weibull Curve or the Wind Turbine’s Power Curve.

Weibull Curve

W’wave improves the wind’s Weibull curve of the wind farm, so that the turbine can extract more energy from the site according to its power curve.

Power Curve

Or, seen from another perspective, W’wave improves the power curve of the turbine under the original wind’s Weibull curve of the wind farm.

Our Products

At present, our product design portfolio consists in fix structures anchored to the ground that act as large wind breakers. We call our Products WindWave Concentrators, or simply… the WindWaves.

We have prioritized low-complexity and robust design concepts with the following advantages:

- Safety: Complying with Building Code standards.

- Business case certainty: Long lifetime (>50 years), and negligeable O&M costs.

- Available Supply chain: Using standard and off-the-shelf components with diversified sourcing origins.

- Reusability & Recyclability: Designing for easy installation and de-installation to reuse them in several wind farms, and/or with potential to be recycled.

- Low carbon supply chain: For some components and suppliers, components can be low-CO2 certified.

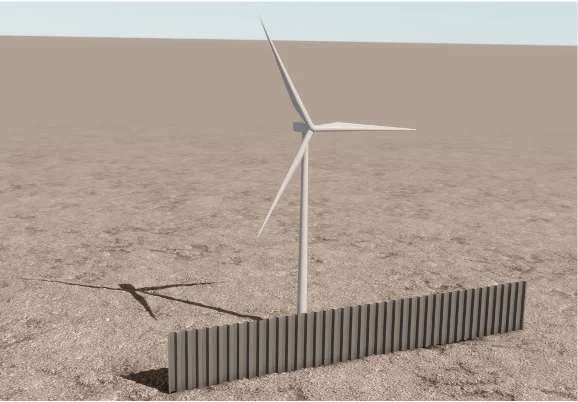

Steel Sheet Pile (SSP) WindWave Design

Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall. Steel sheet piles are constraint on having suitable soil characteristics. It provides a simple installation process, a minimal use of land, and a very short and traceable bill-of-materials with reusage and recycling possibilities.

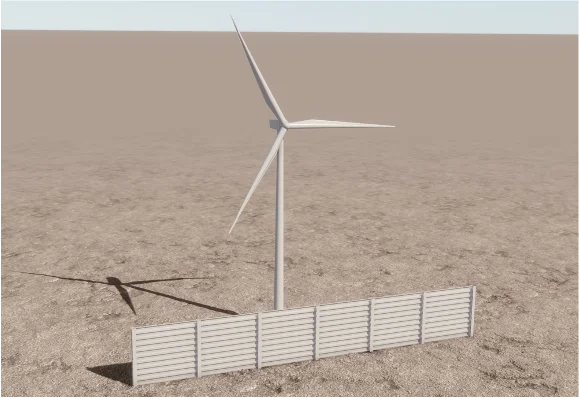

King Post (KP) WindWave Design

The King Post design involves the construction of a wall by combining H-beams as columns and struts that sustain infill components. The columns and struts are anchored either directly in the ground through hammering or vibration or through a concrete foundation. The advantage of this design is its universality, not depending on specific soil conditions.

Designs with other materials (concrete, wood, glassfiber), or even reusing the material from used blades, are Work-In-Progress.

Hybridization with solar PV and natural elements like trees will be tested in the near future (see Projects section).

Technology Use Cases

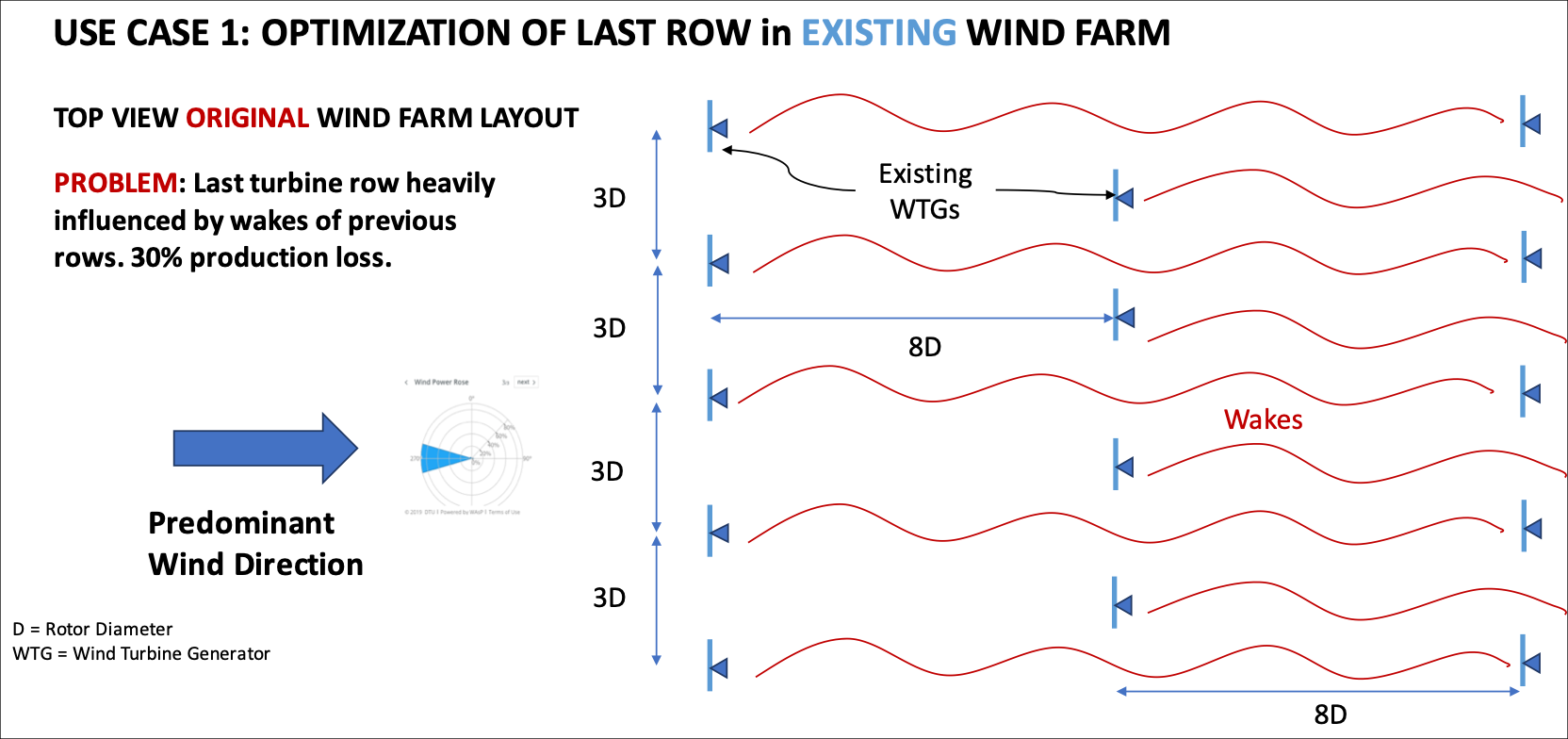

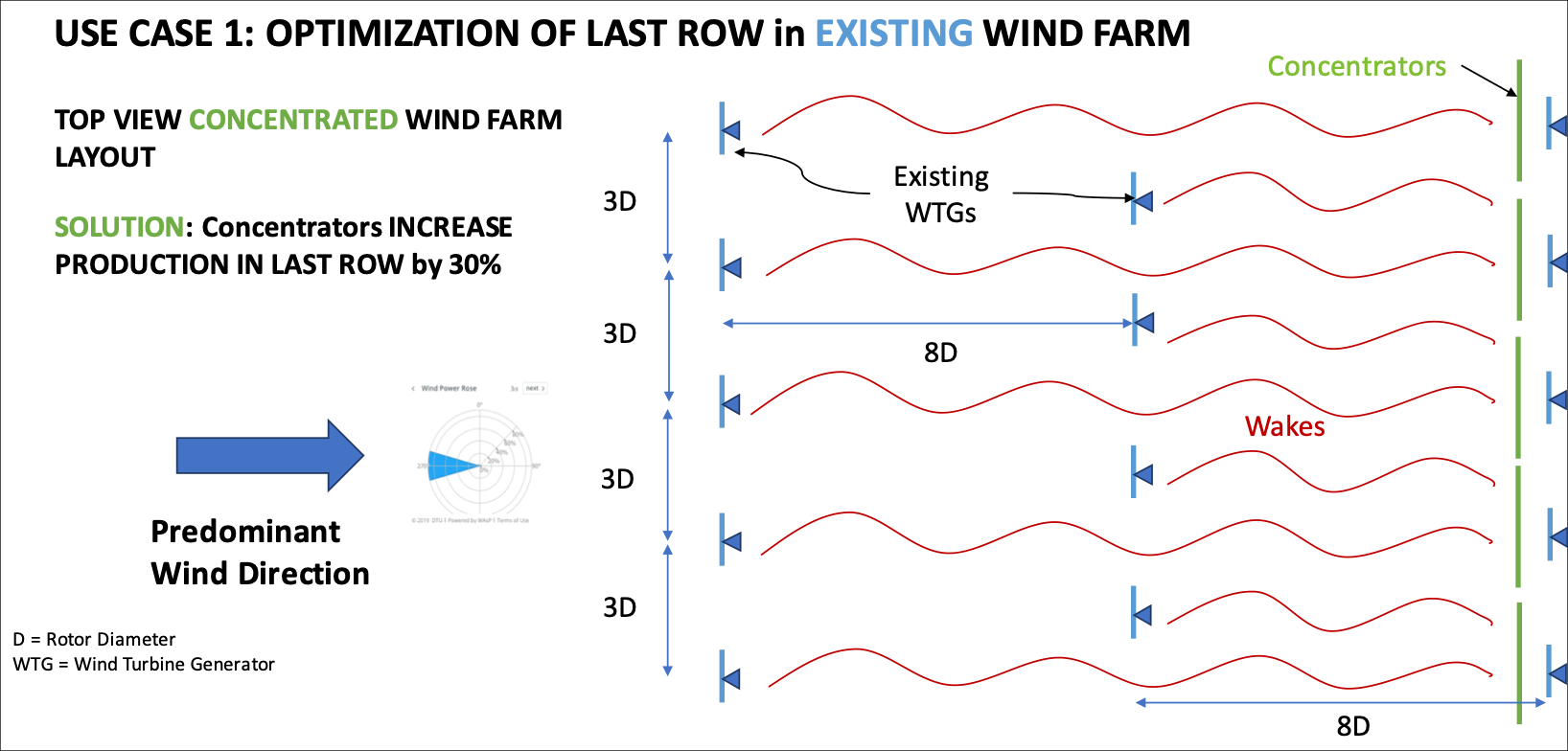

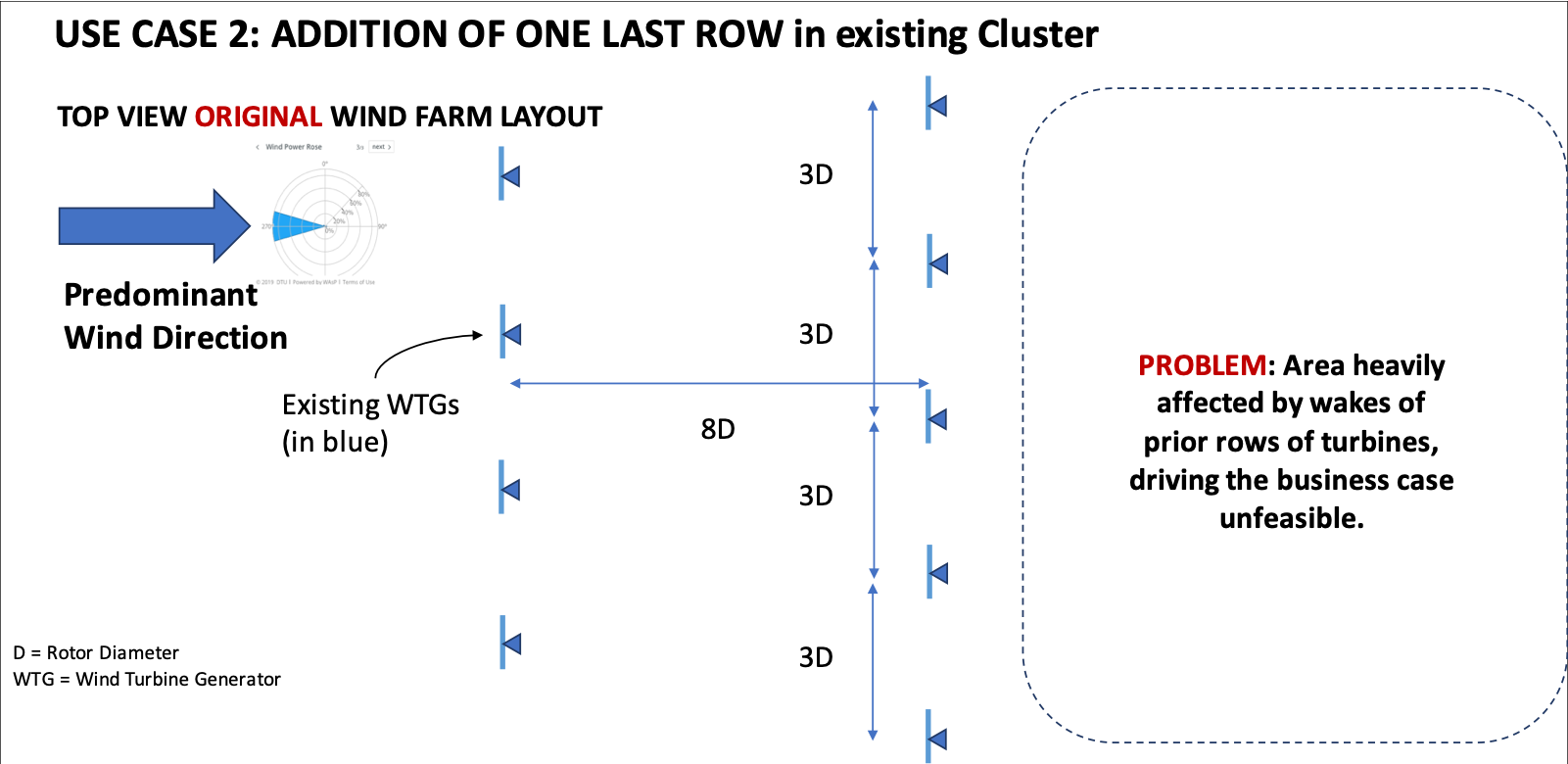

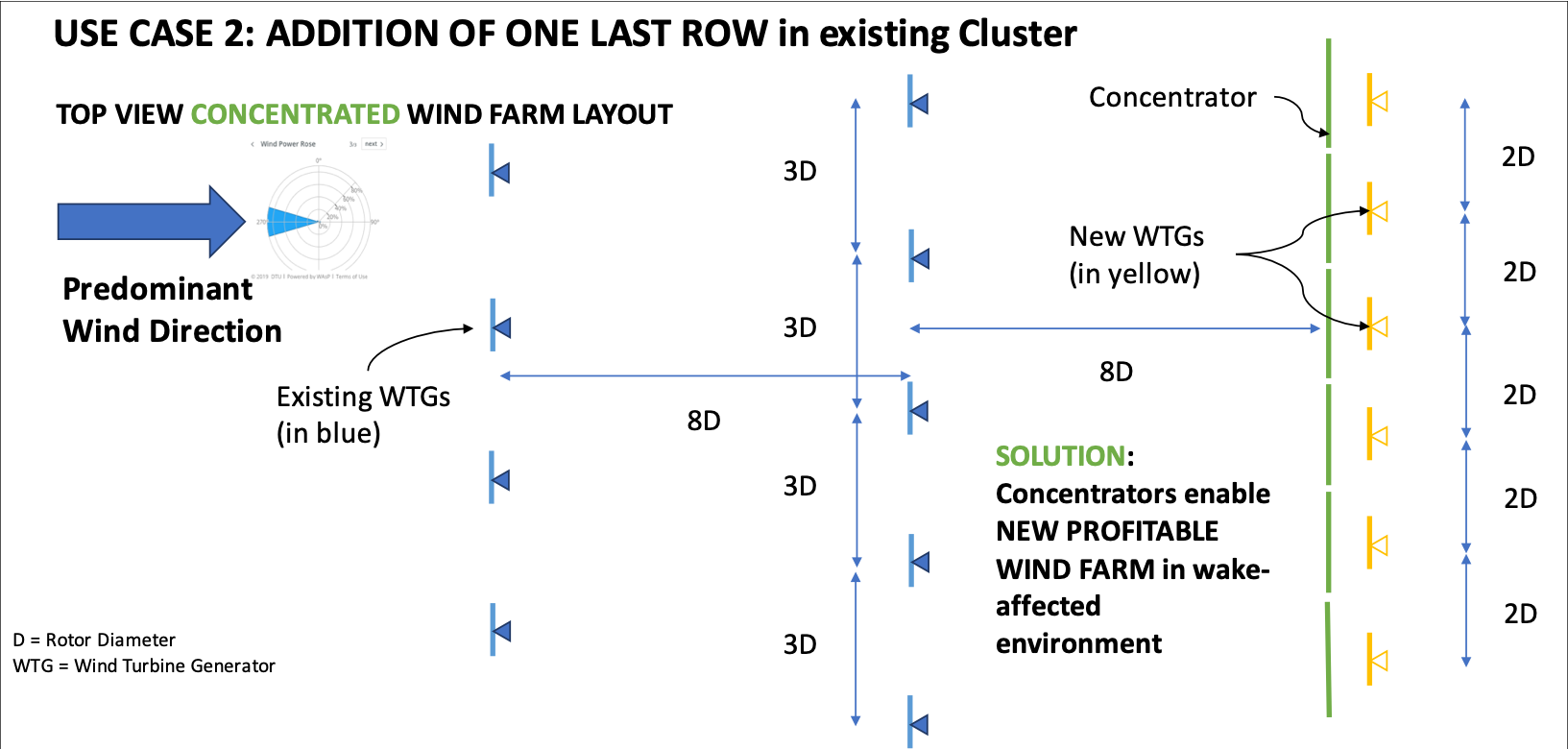

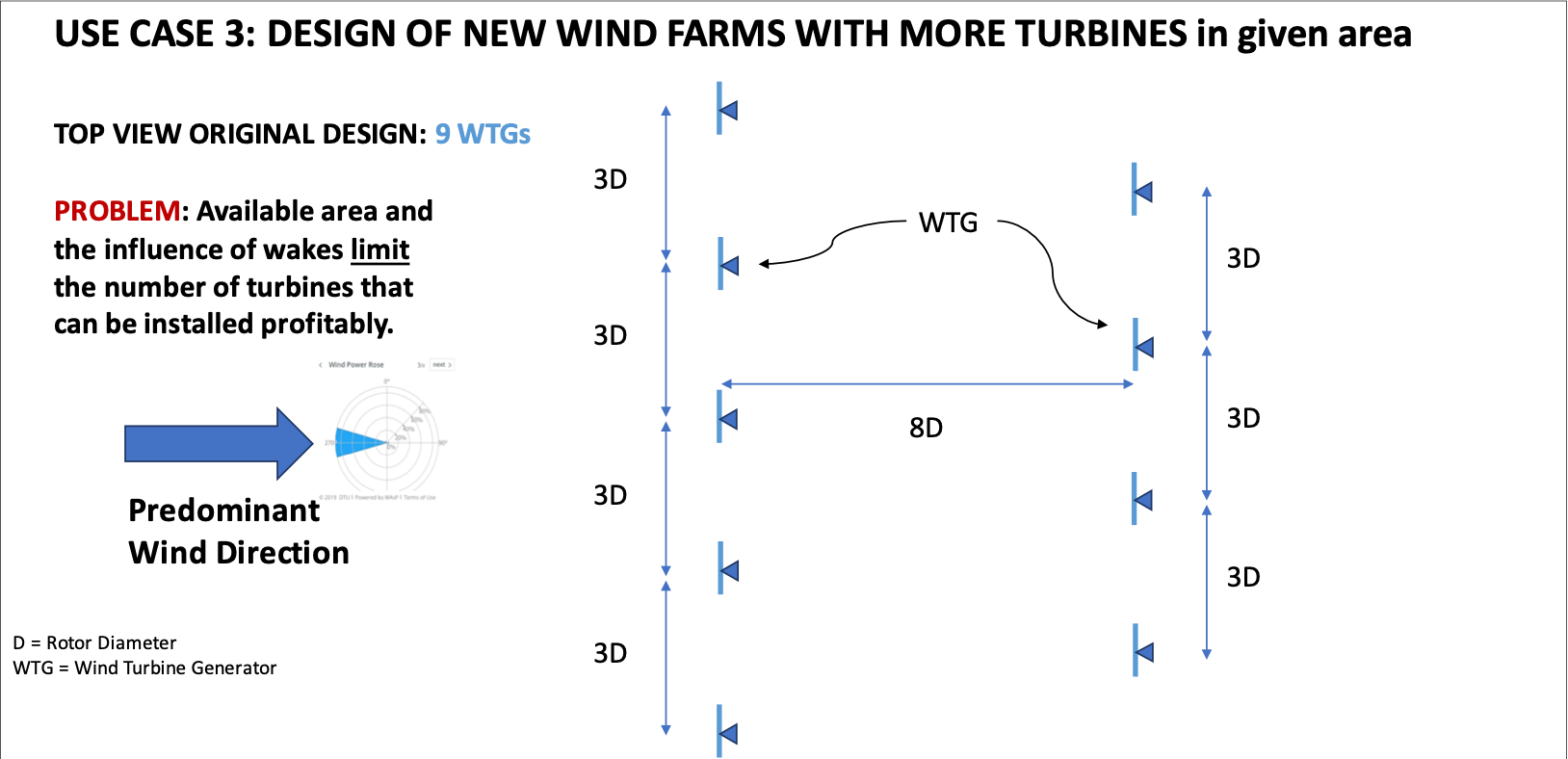

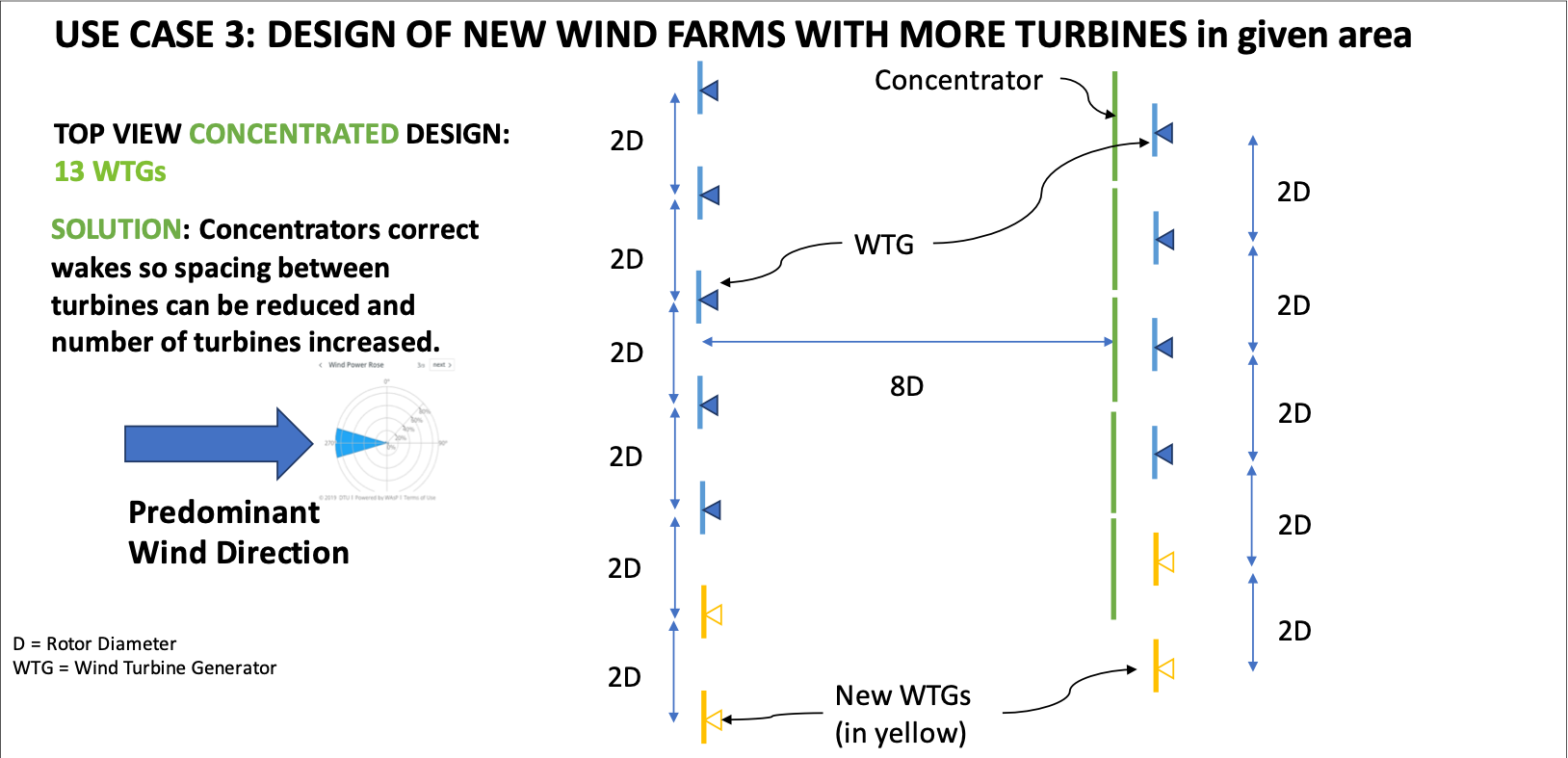

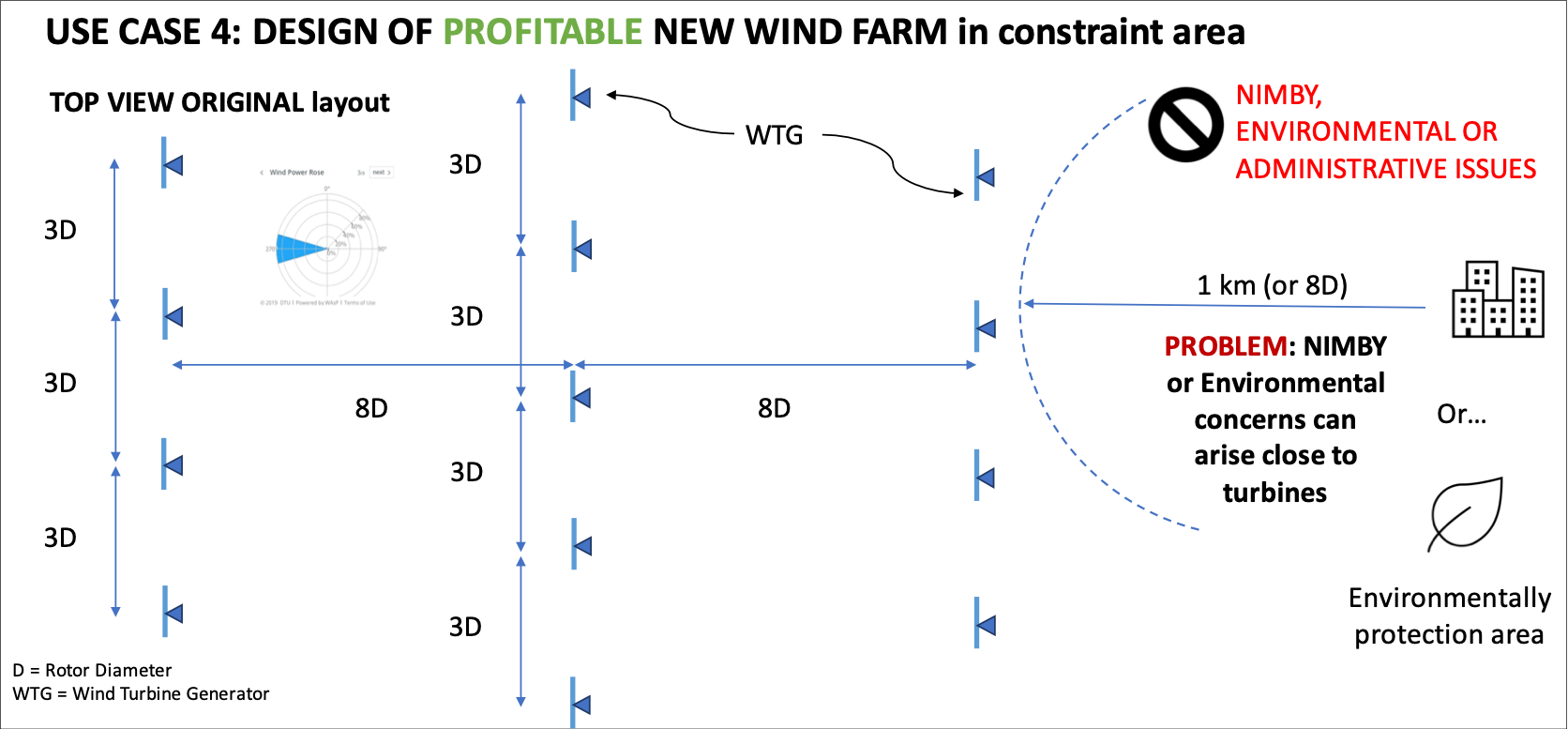

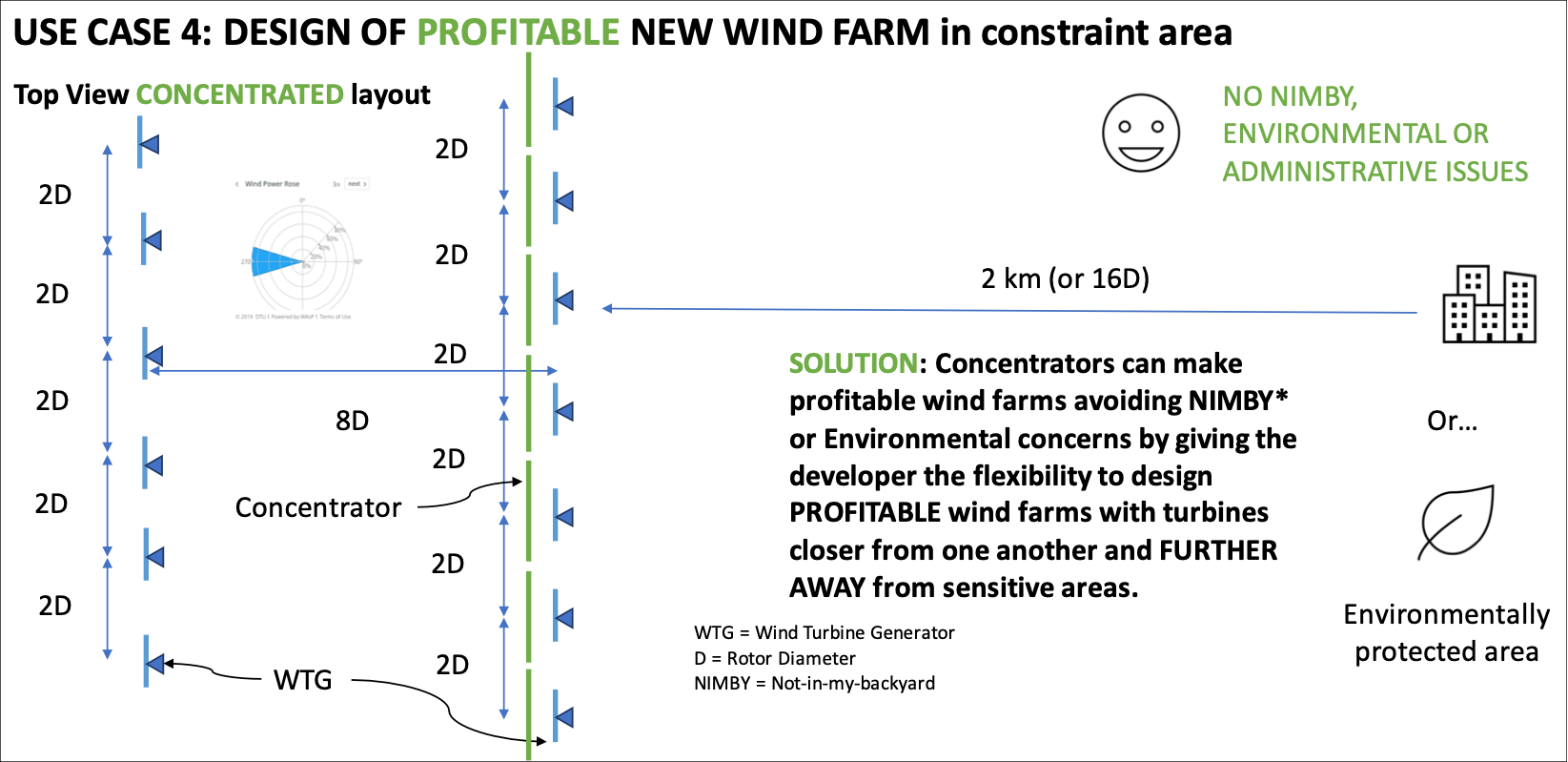

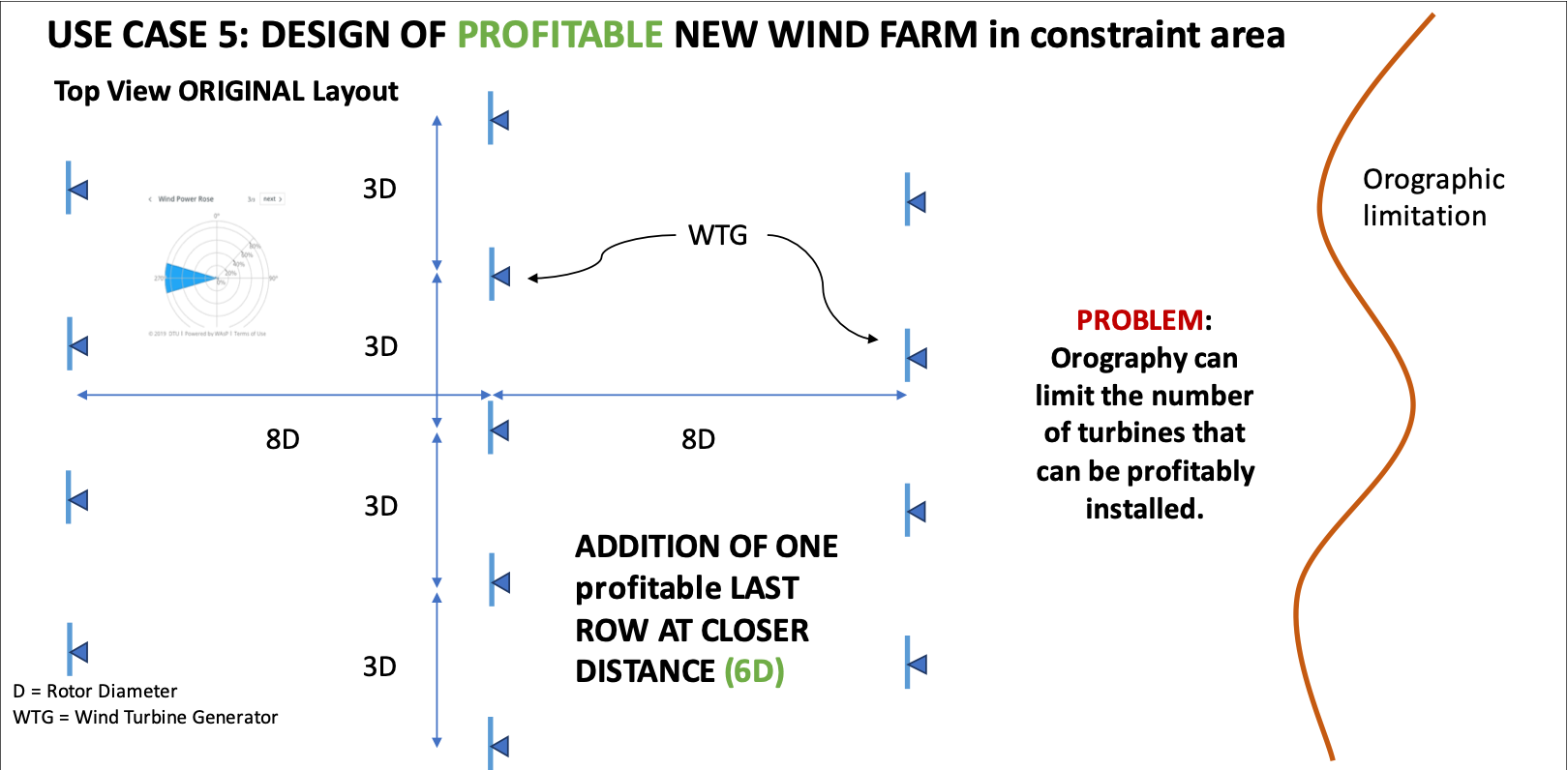

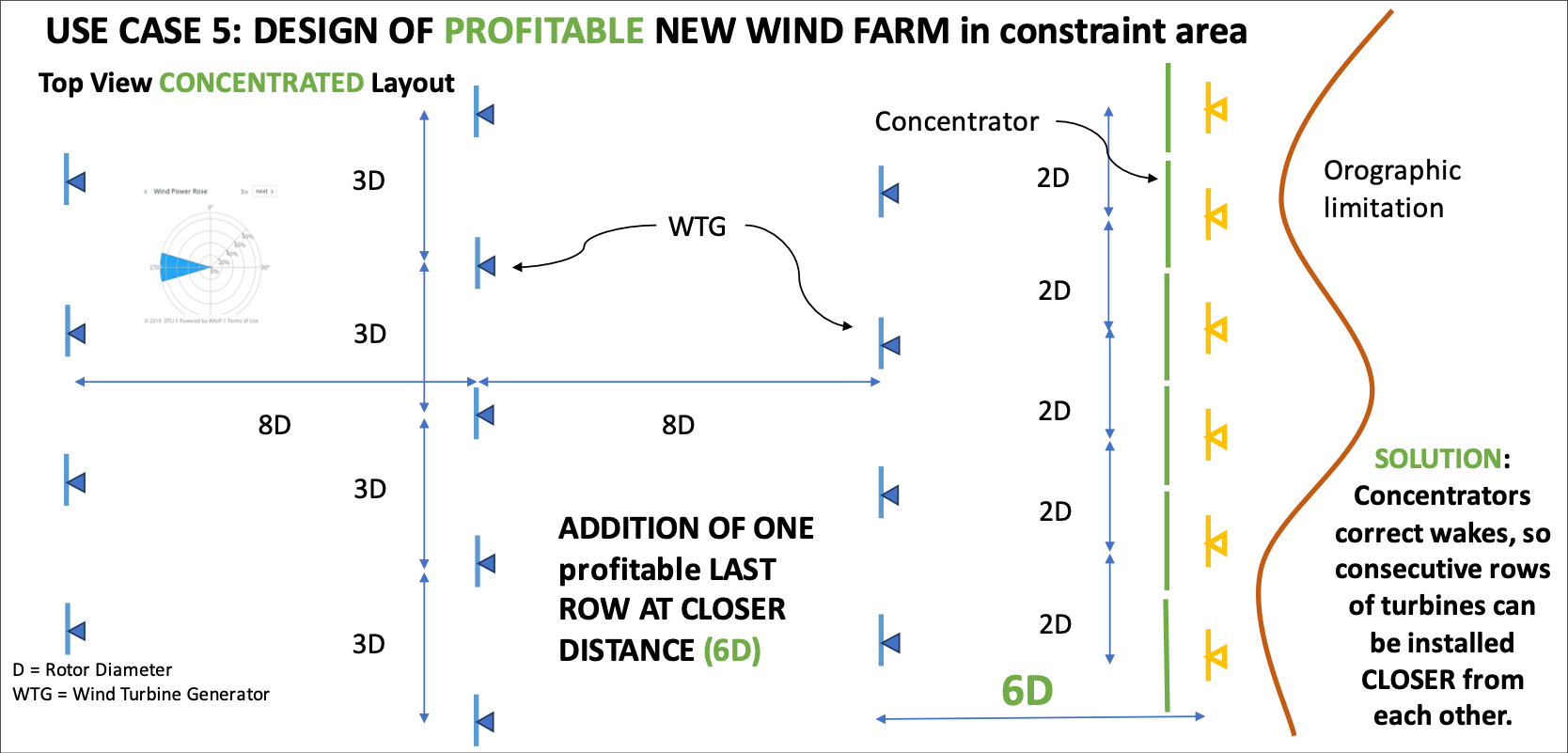

Reducing wind farms design constraints due to wake correction.

One of the key value propositions of W’wave’s Concentrated Wind Power Technology is to provide FLEXIBILITY to wind farm designers to DESIGN MORE POWERFUL WIND FARMS.

W’wave has realized the potential of our Concentrators to reduce the impact of wakes.

Wakes are responsible for severe wind speed reduction and turbulence increase that forces wind farm designers to space wind turbines considerably.

Credits: From “Large eddy simulation studies of the effects of alignment and wind farm length, J. Renew. Sustain. Energy 6, 023105 (2014) ”, by R.J.A.M. Stevens, D. F. Gayme, C. Meneveau; Visualization made by David Bock (XSEDE (Extreme Science and Engineering Discovery Environment)

W’wave® WindWaves reduce wakes.

With our Concentrators the rows of a wind farm that are most affected by wakes can become very productive even at closer distances from the previous row, which enables to reduce the turbine-spacing constraints for wind farm designers.

Find below a set of Use Cases of simplified design visualizations for wind farm design optimization:

Do you think that your wind farm could Benefit from our Solutions?

We can provide an analysis of your specific wind farm.

Intellectual property

W’wave® has heavily invested in Wind Technology Research and has generated Intellectual Property Rights protecting its technology. We are nonetheless open to license our Intellectual Property.

We have 5 patent families in different development stages that aim at protecting:

How much can W’wave® Concentrators increase wind production?

- Production increase from W’wave® Concentrators can attain more than 35% of the original turbine production.

- Levelized cost of energy of the extra energy produced by our Concentrators can go lower than 20 $/MWh.

Investment payback period can go as low as 2 years.

It depends on many factors: The specific Concentrator design parameters (height, length and relative position to the wind turbine), the wind turbine characteristics (nominal power, rotor size, hub height) and the site characteristics (orography & layout).